Table of Contents

ToggleA fan can be defined as a volumetric machine that moves quantities of air or gas from one place to another. During this process, energy transfer occurs from the machine to the fluid, converting mechanical energy into fluid energy.

Fans, blowers, compressors, and pumps belong to the category of machines where energy transfer occurs from the machine to the fluid, whereas turbines operate in the reverse manner, transferring energy from the fluid to the machine.

Fans consume power as they rotate using a prime mover, whereas turbines rotate due to fluid energy and help in generating power. Fans play a vital role in industries, HVAC systems, and power plants, facilitating processes that range from simple ventilation to complex thermal management.

Types of Fans

Fans can be classified into two major types based on the direction of fluid flow in the impeller:

- Axial Flow Fans

- Radial (Centrifugal) Fans

Axial Flow Fans

In axial flow fans, the main flow is parallel to the axis of rotation of the fan at both entry and exit. These fans can be further categorized into:

Impulse Type

In impulse-type fans, most of the energy coming out of the impeller is kinetic energy, which is converted into pressure energy in the outlet blades and diffuser. Hence, they are known as impulse fans. These fans are commonly used in scenarios where quick acceleration of air is required.

Reaction Type

In reaction-type fans, most of the energy from the impeller is in the form of pressure energy. The degree of reaction (R) is defined as:

For impulse fans, , whereas for reaction fans, . The pressure rise of a fan can be increased by staging, where multiple impellers are arranged in series to achieve the desired pressure. Reaction fans are commonly used in power plants and heavy industrial processes where significant pressure rises are necessary.

Radial (Centrifugal) Fans

Radial fans are categorized based on the configuration of the blades relative to the direction of impeller rotation. The primary types include:

- Backward Curved (B.C.) Blades: Exit blade angle < 90°

- Forward Curved (F.C.) Blades: Exit blade angle > 90°

- Radial Blades: Exit blade angle = 90°

Backward-curved blades are the most efficient and commonly used. Forward-curved blades are less efficient and have overloading characteristics, consuming more power. Radial bladed fans are simpler in design and are preferred for applications involving high particulate loads, such as dust or ash.

Fan Designation

Fans are often designated based on specific configurations:

Radial Fans:

- NDFV Y Z: Single suction with inlet guide vane control.

- NDV Y Z: Single suction, simply supported impeller.

- NDZV Y Z: Double suction, simply supported impeller.

Axial Fans:

- A N M C6: Non-profiled blades with a diffuser.

- A P X Y Z: Profiled blades with staging and dimensional details.

This designation system simplifies the selection process by providing clear parameters for each fan type.

Advantages and Disadvantages of Axial Fans

Advantages:

- Smaller physical size compared to centrifugal fans of similar capacity.

- Cost-effective.

- Efficient and rapid control with variable pitch impeller blades.

Disadvantages:

- Higher noise levels due to high tip speeds.

- Blades are prone to erosion at high speeds.

- Requires careful sealing of pitch-change gear to prevent dust ingress.

Axial fans are typically used in HVAC systems, cooling towers, and situations requiring high airflow rates at low pressure.

Advantages and Disadvantages of Radial Fans

Advantages:

- Higher efficiency compared to axial fans.

- Easier to repair on-site.

- Lower noise levels.

Disadvantages:

- Higher initial and operating costs.

- Larger physical size compared to axial fans.

Performance Characteristics

The performance of centrifugal fans follows fan laws:

- Capacity: Proportional to fan speed (N).

- Head: Proportional to .

- Power Input: Proportional to .

Backward-curved blades are suitable for high motor speeds, offering efficient operation without overloading. Forward-curved blades are preferred in applications like induced draft (ID) fans to minimize erosion caused by fly ash. Centrifugal fans find extensive use in industrial settings, boiler systems, and pneumatic conveying.

Control of Fan Output

Necessity of Control

Fan output control is essential to accommodate varying load conditions, from boiler light-up to full load operation. Additional capacity is required to account for boiler fouling and adverse conditions. Control mechanisms ensure the operational efficiency and longevity of fan systems.

Methods of Control

- Damper Control: Acts as a throttle to restrict fan output. Advantages include low initial cost and ease of automation. However, it is inefficient due to energy dissipation by throttling. Dampers are commonly used in smaller systems or where cost constraints exist.

- Inlet Vane Control: Introduces spin to the air or gas in the fan’s direction of rotation, reducing power input. It offers better efficiency than damper control but cannot reduce flow below one-fourth of full output effectively. This method is suitable for larger systems where moderate efficiency gains are desired.

- Variable Speed Control: Most efficient in terms of power consumption. Achieved using variable-speed AC or DC motors, or mechanical/hydraulic couplings. High initial costs are a limitation but are justified in large-scale, energy-intensive systems.

- Blade Pitch Control: Used in axial reaction fans. The angle of entry is adjusted during operation using a hydraulic servomotor. This method provides precise performance control and is widely applied in advanced systems.

On large modern plants, dampers and control equipment are often operated remotely from a central control room. Local control and manual operation facilities are typically provided for emergency use.

Recent posts

Related posts:

- Rankine Cycle in Thermal Power Plants

- Modes of Coal Transportation in Power Plant

- Coal Handling Plant – CHP

- Protections in Coal Handling Plants and Challenges

- Fuel Firing in Boiler

- Boiler Construction: History, Types, and Key Components

- Bowl Mill (Pulverizer) in Thermal Power Plant

- Coal Feeders in Power Plants

- Construction and Working of Air Preheater

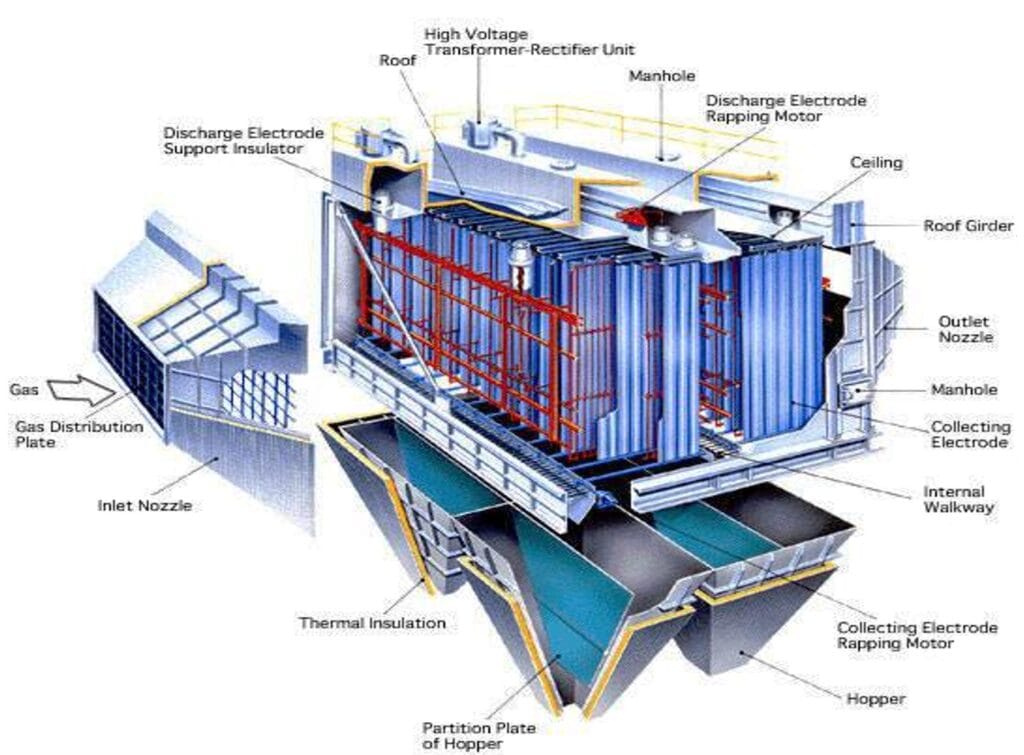

- Electrostatic Precipitators (ESP)

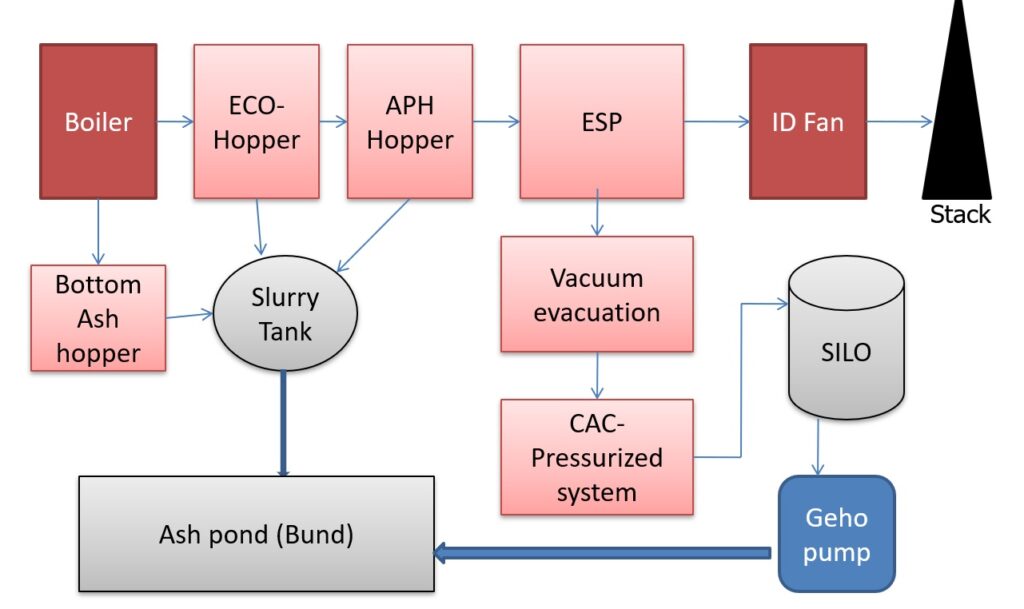

- Ash Handling Plant