Table of Contents

ToggleIn thermal power plants, coal is a critical fuel used to generate electricity. Efficient transportation of coal from mines to the power station is essential to ensure a steady supply. Various modes of coal transportation are employed depending on the distance, capacity, and infrastructure available.

Coal is transported to power stations through three primary modes which include roadways, railways, and ropeways:

Roadways

Coal is carried in trucks, with each truck capable of carrying about 8-10 tons of coal. However, due to the low capacity, slow unloading rate, and time-consuming nature of this method, road transportation is rarely used for large thermal power stations.

Railways

Coal is transported by railway wagons. A single rack consists of 58 wagons, each containing 58 MT of coal. Locomotives bring the wagons from the marshalling yard and position them on a wagon tippler, which unloads the coal.

If the wagons are not unloaded within the stipulated time (typically 7 hours), demurrage charges are imposed by the railway department.

There are two types of wagon tipplers:

Side Wagon Tippler

- The wagon is tilted to the side into a hopper beside the railway track.

- The maximum tilt angle is generally between 140° to 150°.

- The unloading rate is 13 wagons per hour.

Cycle of Operation for Side Wagon Tippler:

- Weighing wagon + coal before tippling – 15 sec.

- Tippling wagon to the hopper – 90 sec.

- Pause – 5 sec.

- Returning the wagon to the home position – 90 sec.

- Weighing wagon after tippling – 15 sec.

The weighing machines are integrated into the tippler mechanism, fitted with a ticket-printing recorder and a totalizer.

Ring Type (Rotary) Wagon Tippler

- In this system, the wagon is placed between two large rings that form a cage-like structure.

- The cage rotates, causing the coal to fall into the hopper below the rail track.

- The tilt angle is between 140° and 160°.

- The unloading rate is 25 wagons per hour, and one complete cycle takes only 60 seconds.

For efficient wagon movement, mechanized beetle chargers are provided both before and after the wagon tippler (inhaul and outhaul beetle chargers). These tipplers are also equipped with photocell protection to prevent other wagons from entering during the tippling cycle.

- Track Hopper System:

In some Thermal Power Station, coal is unloaded from BOBR (Bottom Opening) Wagons into track hoppers with a capacity of 4,500 MT.

- MGR Railway System:

- This system is used when coal mines are located near the power station. Railway wagons transport coal from the mines to the station, and the empty wagons are returned for refilling, creating a continuous loop.

- This is the most economical method of coal transportation, with minimal maintenance time and cost compared to the ropeway system.

Ropeways

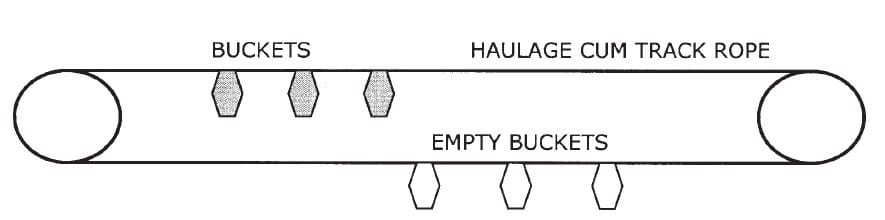

This method is used when coal mines are close to the power station. Coal is transported in hanging buckets or trolleys that travel on track ropes, pulled by a haulage rope with a driving mechanism. Each bucket can carry 1 to 3 tons of coal.

Automatic loading and unloading mechanisms are present at both ends. The unloading rate ranges from 75 to 275 MT/hour, depending on the type of ropeway system used. This method is more economical than road or rail transportation, with a reliable coal supply. However, it requires longer maintenance times.

There are two main types of ropeway systems:

Mono-Cable Ropeway

- This system operates on a single endless haulage rope that both supports and hauls the ropeway bucket.

- The buckets are firmly attached to the moving rope and travel automatically, requiring no operator attention.

- Each bucket has a capacity of 1.0 T/hr, and the total line capacity is 75 T/hr.

Bi-Cable Ropeway

This system is further divided into two types:

a) Tram Car Type Ropeway:

- Two track ropes are provided: one at the top to carry full cars and one at the bottom for empty cars.

- Each tram car has an axle at both ends and runs on six wheels. The cars flip completely upside down during unloading and back upright during loading, eliminating the need for extra discharge mechanisms.

- Each bucket has a capacity of 2.5 T/hr, and the line capacity is 200 T/hr.

b) Bi-Cable Bucket Type Ropeway:

- This system uses two tensioned fixed track ropes. One carries full buckets, while the other carries empty buckets.

- The buckets are attached to a continuously moving haulage rope.

- The track ropes are supported by intermediate trestles, which are equipped with oscillating saddles and sheaves.

- The capacity of each bucket ranges from 1.8 to 2.5 T/hr, and the total line capacity is between 200 and 275 T/hr.

Conclusion

Each mode offers unique advantages, such as railways being widely used for large volumes, while ropeways provide a cost-effective solution when mines are close to the plant. These systems ensure smooth coal delivery, minimizing disruptions in power generation.