Table of Contents

ToggleEarthing: An Essential Component of Electrical Safety

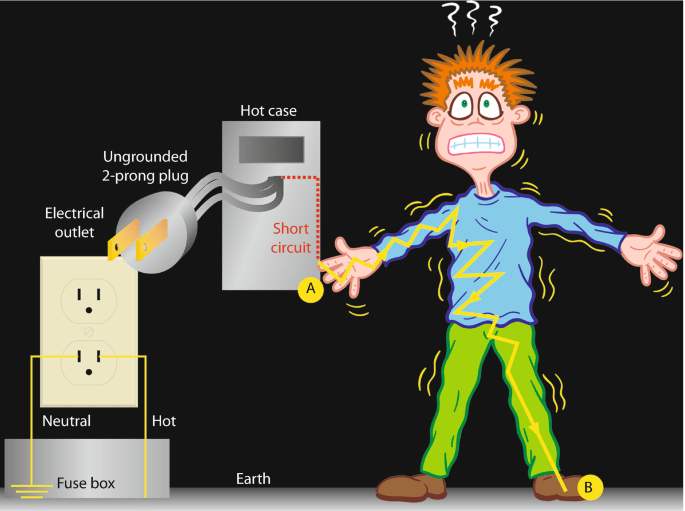

Electricity is one of the most significant discoveries in human history, and it powers most of our modern-day gadgets and technology. However, as beneficial as electricity is, it can also be incredibly dangerous, causing electrical shocks, fires, and even fatalities. That is why proper electrical safety measures, such as earthing, are essential.

What is Earthing?

Earthing is the process of connecting a device or equipment to the ground, which provides a safe path for any excess electrical current to flow into the ground. Earthing is an essential part of electrical safety as it prevents electrical shocks, fires, and equipment damage.

Where is Earthing a Must?

Earthing is necessary in all electrical systems, including homes, offices, factories, and other industrial settings. Any electrical device or equipment that is not earthed properly can pose a serious threat to people’s safety.

Need of Earthing

The primary reason earthing is necessary is to ensure electrical safety. When an electrical device or equipment is properly earthed, it provides a safe path for any excess electrical current to flow into the ground, preventing potential electrical shocks or fires. Additionally, earthing helps to reduce electrical noise, which can interfere with the proper functioning of electronic devices and equipment.

Types of Earthing

There are several types of earthing, including plate earthing, rod earthing, pipe earthing, and strip earthing. Each type of earthing has its advantages and disadvantages, and the type of earthing used depends on the specific requirements of the electrical system.

Plate earthing, rod earthing, pipe earthing, and strip earthing are the most common types of earthing used in electrical systems. Here’s a brief overview of each type:

- Plate Earthing: In plate earthing, a copper or galvanized iron plate is buried in the ground, and the electrical device or equipment is connected to the plate through a copper wire. The plate is usually buried vertically, and it should have a minimum size of 600mm x 600mm x 3mm. This type of earthing is suitable for small electrical systems.

- Rod Earthing: In rod earthing, a copper or galvanized iron rod is driven into the ground, and the electrical device or equipment is connected to the rod through a copper wire. The rod should have a minimum length of 2.5 meters and a diameter of 12.5mm. This type of earthing is suitable for larger electrical systems.

- Pipe Earthing: In pipe earthing, a galvanized iron or copper pipe is buried vertically in the ground, and the electrical device or equipment is connected to the pipe through a copper wire. The pipe should have a minimum length of 2.5 meters and a diameter of 40mm. This type of earthing is suitable for dry soil conditions.

- Strip Earthing: In strip earthing, a copper strip is buried horizontally in a trench, and the electrical device or equipment is connected to the strip through a copper wire. The strip should have a minimum width of 25mm and a thickness of 3mm. This type of earthing is suitable for rocky soil conditions.

Each type of earthing requires proper installation and maintenance to ensure it is effective in protecting against electrical hazards. It is important to consult a qualified electrician or engineer for the proper design and installation of an earthing system.

Each type of earthing has its advantages and disadvantages, and the type of earthing used depends on the specific requirements of the electrical system. It is important to choose the appropriate type of earthing to ensure proper electrical safety.

Advantages of Earthing

- Protection from electrical shocks and fires.

- Reduced electrical noise.

- Increased equipment life.

- Reduced maintenance costs.

- Compliance with electrical safety standards.

Alternatives of Earthing

While earthing is the most common method of electrical safety, there are alternatives, such as isolation transformers and residual current devices. However, these alternatives are not as effective as earthing, and they may not provide the same level of protection.

In conclusion, earthing is an essential component of electrical safety that should not be ignored. It is necessary to protect people, equipment, and buildings from electrical hazards. Understanding the importance of earthing and implementing proper earthing techniques can prevent electrical accidents and save lives.

How to DO Earthing? (Procedure)

Earthing is done by creating a conductive path between the electrical device or equipment and the ground. The method of earthing may vary depending on the type of electrical system and the local regulations. Here’s a general overview of the steps involved in earthing:

- Identify the type of earthing required based on the electrical system’s specifications and the local regulations.

- Choose the appropriate location for the earthing system, considering factors such as the type of soil, the presence of water, and the distance from the electrical device or equipment.

- Prepare the earthing system, including the earthing electrode, the conductor, and the earth pit. The earthing electrode may be a copper or galvanized iron rod, plate, or pipe.

- Connect the electrical device or equipment to the earthing electrode using a copper conductor. The conductor should be insulated and have a cross-sectional area sufficient to carry the maximum fault current.

- Create an earth pit near the earthing electrode by digging a hole in the ground and filling it with a mixture of charcoal and salt. The earth pit should be at least 1 meter deep and 1 meter wide.

- Connect the earthing electrode to the earth pit using a copper conductor. The conductor should be buried at least 1 meter deep in the ground and should be protected from physical damage.

- Test the earthing system to ensure it is properly installed and functioning correctly. Testing may involve measuring the resistance of the earthing system, checking the continuity of the conductor, and ensuring that the system meets the local regulations and safety standards.

It is important to have a qualified electrician or engineer design and install the earthing system to ensure proper safety and compliance with the regulations. Regular maintenance and testing of the earthing system are also essential to ensure its effectiveness in preventing electrical hazards.

Why Charcoal and Salt are Used in Earthing?

Charcoal and salt are used in earthing because they help to improve the conductivity of the soil around the earthing electrode. Here’s how it works:

Charcoal is a porous and conductive material that can absorb and retain moisture, which is important for maintaining a low resistance path to the ground. When charcoal is mixed with the soil around the earthing electrode, it helps to improve the soil’s conductivity by providing a more conductive path for the electrical current to flow through.

Salt is used in earthing to reduce the soil’s resistance and improve the conductivity of the earthing system. Salt ions are highly conductive and can help to create a conductive path between the earthing electrode and the surrounding soil.

When charcoal and salt are mixed together and placed in the earth pit around the earthing electrode, they can help to create a low-resistance path to the ground, which is important for ensuring the proper operation of the earthing system. However, it is important to note that the amount of charcoal and salt used should be appropriate for the soil type and local regulations, and a qualified electrician or engineer should be consulted to ensure proper installation and compliance with the safety standards.

Recent posts

No related posts.